Packaging in today’s world is one of the most important product introduction tools, which increases the market share for various products. In general, the products on the market are produced with similar processes and technologies, but what makes the price difference in similar products is the difference in packaging and related innovations. Water bottles are no exception to this rule, due to their great variety in the market. Water bottle design with PET technology can play an effective role in sales.

Raw material for water bottle production

Before we start designing PET water bottles with PET technology, it is better to explain about PET. PET is stands for polyethylene terephthalate.this is the ideal material for making PET bottles that has significant properties. Some of these features for bottle production include:

- PET has high strength to weight ratio; As a result, bottles made of PET have high strength and resistance to breakage and crushing.

- PET is resistant to temperature and heat penetration; This feature helps to ensure that the contents of the bottle are safe from the outside environment.

- PET compared to other raw materials in the production of bottles, like glass and metal has low weight; Therefore, PET bottles are lighter than metal or glass bottles.

- PET is cheap and affordable. The low price of PET bottles, compared to glass or metal bottles, is significant and has attracted the attention of manufacturers.

- PET has high flexibility and so by designing a bottle with PET technology, you can implement your creative ideas in different ways.

- PET has a high recyclability and compared to other raw materials, produces less greenhouse gases; The result is environmentally friendly.

Water bottle design with PET technology

As mentioned, today product packaging is an indicator of product sales. In addition to this, put the flexibility of PET Now you can creatively design water bottles with PET preform technology. Of course, your distinctive idea will be seen in the market, so do not worry about the time and expense you incur. Creating a new idea is the first step in designing a water bottle with PET technology. At the beginning, you must according to the desired features, get a basic idea and then cultivate it. Now you have to draw your idea based on the capabilities of computers and the use of 3D design software. When designing, special attention should be paid to the characteristics of PET as well as the specifications of the final product and its application.

After that, it is necessary to make a sample of the design in order to be able to make the necessary corrections and changes physically. Finally, with the approval of the plan, should be thought of production. Before entering the bottle production stage, it is necessary to implement your design as a preform mold in which the raw materials are formed and the bottle is made. Because PET bottles are difficult to transport, for convenience, the transfer of these products is done in preform or pre -PET In fact, it can be said that the preform is a product that (blow molding stage) turns into a PET bottle.

Making preform molds in turning

After designing the water bottle with PET preform technology, it is necessary to making mood. The Mold should be such that it applies all the details of the design well. Molds are usually made of iron alloy and require a skilled lathe maker to make them. These molds are heavy and cause friction, vibration and noise of the device. Change the mold, for the appearance variety of the bottle, requires high skill and it takes a lot of time which is very time consuming and troublesome for the owners of the bottle production line. Although iron molds are used and can meet the needs of the production line, But the use of flexible plastic molds that are also strong, increases the efficiency of the work significantly.

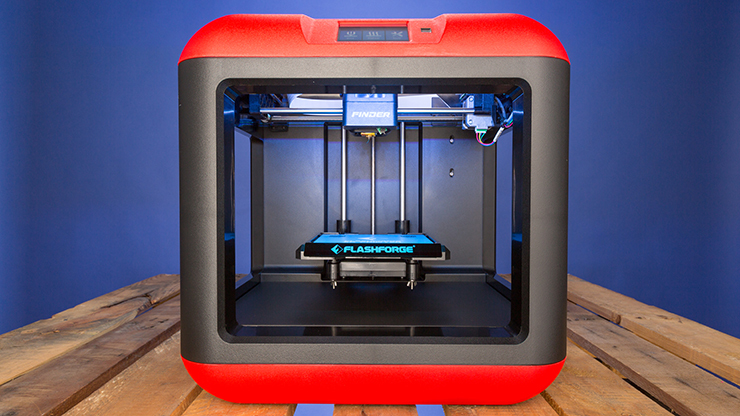

3D printer

An easier and faster solution for designing PET water bottles with PET technology is to use a 3D printer. A 3D printer is a device for producing 3D designs using additive manufacturing technology. Various plastic bottles and even their lids can be made with this technology. Wind injection molds are produced using pla filament and industrial 3D printers. 3D printing services are affordable and inexpensive; In addition, it has a very high accuracy and can provide you with the design with all the details and highlights.

Using a 3D printer speeds up the process and you can create a large number of creative designs for your water bottle in a short period of time. This difference helps you to stand out from the crowd. As a result, your market dominance is certain.

PET bottle production

After designing water bottle with PET technology and making mold, we enter the production stage. First, the PET raw material, which is in the form of granules, is poured into the injection machine. this is by suction and with the aim of producing molds in size and different weights After some steps, this material heats up and then softens and is converted into a paste and injected into the preform mold. After this step, the produced preform, after cooling and hardening, is taken out of the mold and directed to the blower device.

In the wind section, the PET preforms made by the machine heats up and softens so that it is neither too hot nor too cold, because too much heat and cold will both destroy the preform. The softened preform is placed inside the blower and inflated as desired. This amount depends on the type of mold, size and weight of the preform. Finally, the product is cooled and the bottle is removed from the mold.

Tips for producing PET bottles

PET bottles are resistant to transfer and water, carbon dioxide and oxygen will not pass easily. This property allows us to thin the wall of the bottle as much as we want. Therefore, less polymer is used in making bottles with suitable efficiency. Solid PET must be very dry to maintain its physical and mechanical properties by preventing its hydrolysis. PET bottles have a very good gloss and clarity, in addition to their weight compared to metal or glass bottles It will save dramatically.

The final word

PET bottles in industry It is one of the most widely used packaging, which is also found in municipal waste and can be recycled. Water bottle design with PET technology Creates this opportunity Use special PET properties and design and manufacture based on it. Dorfam Company, with its brilliant history and use of the latest technologies, Has the ability to design and manufacture a variety of PET bottles and can accompany you on the packaging and production line.