Dorfam; A careful look at how to make a variety of pneumatic injection products.

blow molding products are a branch of polymer products widely used in the packaging industry. Variety in design, color, and excellent moldability to provide creative packaging solutions, competitive price, and cost efficiency are among the advantages of this type of packaging. At Dorfam Company, we can provide our customers with various kinds of these products for different purposes.

What are Extrusion Blow Molding products?

Extrusion Blow Molding products are any polymer products produced in molten form by various pneumatic molding processes and by injecting air into the raw material. This method is used to make multiple stock products and containers and bottles of finished products in the packaging industry.

Types of Extrusion Blow Molding products

The Extrusion Blow Molding produces various pneumatic products for packaging all kinds of pharmaceutical, food, and chemical products. The manufacturing of blow molding products has revolutionized the packaging industry, and the scope of these products is increasing day by day. Below we will familiarize ourselves with some groups of blow molding products in the packaging industry.

Poison Bottle

You can use Extrusion Blow Molding toxic packaging liquids, pesticides, antifungals, and herbicides. These products can be single layer or multi-layer. The material resistance of these products is also very high. We familiarize ourselves with the advantages of this type of product:

– Resistance to oil and alcohol-based solvents.

– Resistance to collapse

– Various sizes

Detergent bottles and Home Care

With the Extrusion Blow Molding, various products such as bottles and containers for detergents and care products can be manufactured at home. At Dorfam Company, we can offer you different types of these products or make your product. The advantages of these products include:

– Optimal waste disposal

– Recyclability of these products

– Possibility of individual product design

Motor Oil Bottle

The market for motor oils and lubricants demands high-strength, easy-to-handle packaging. Dorfam’s products in this field are characterized by a high degree of impermeability, an appropriate design, and recyclability. The method of these products is such that the doors of these products can be easily opened and closed.

Cosmetic Containers (Personal Care)

The cosmetics industry in packaging needs variety, beauty, ease of use, and strength. The owners of this industry are obsessed with ordering plastic products from various containers and bottles in different shapes with a specific design. The particular design of these products depends on the type of product and cosmetics, the kind of use, and brand objectives.

Background of Extrusion Blow Molding

The idea of Extrusion Blow Molding comes from the traditional method of making bubbles and glassware, which is hundreds of years old. The production of Extrusion Blow Molding using polyester raw materials began in the late nineteenth century. In the twentieth century, companies such as Hartford and Empire made Christmas tree ornaments in this way. Mass production of plastic bottles finally began in the United States in 1939 and spread around the world.

Extrusion wind molding

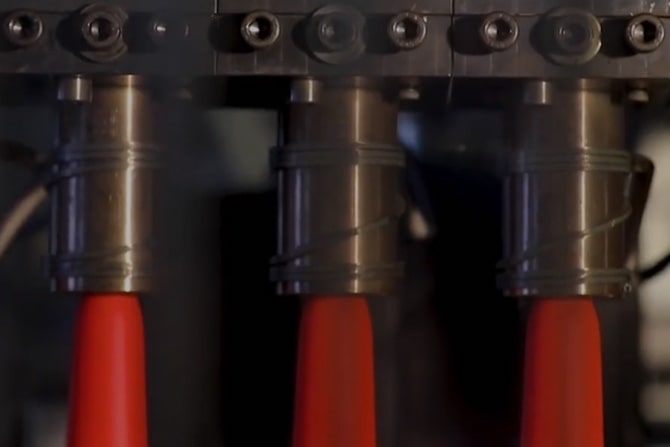

The extrusion blow molding process begins by heating the appropriate polymer in the injection unit, and the semi-molten material enters the molding unit cylindrically from the injection nozzle. After closing this material, the mold holds a cylindrical melt; simultaneously with blowing air into this cylinder, the materials of this cylinder stick to the inner wall of the mold and take the shape of the mold. At the same time, the mold is cooled with water cooling to fix the shape of the final product. Finally, the excess material in the upper and lower parts is cut off with the cutting unit to produce the finished end product. The advantages of this method are:

– Low production costs and a wide range of molds.

– Variety of colors and shapes

– Ability to produce a variety of products with different and complex shapes