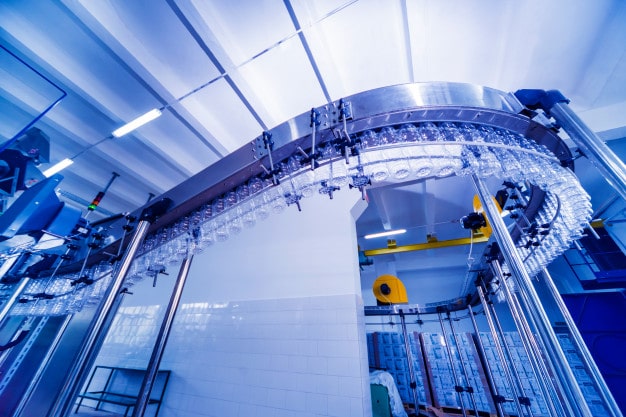

Production of PET bottles at your factory

Many large factories producing beverages, food and dairy products, health and pharmaceutical products and even industrial products face the challenge of packaging, which is a very complex and challenging world. On the one hand, the concerns of production and supply of the final product and on the other hand, the challenges of packaging, quality control, time, cost and double energy.

Dorfam Company has considered an amazing and innovative methods for PET bottle packaging for these manufacturers. By outsourcing the supply of bottles and containers required for products packaging, factories can focus more on the production and supply of final products and leave packaging matters to their factory. In this method, Dorfam will be present at your factory, install and commissioning its machines, place its personnel and specialized staff hostelry, and continuously produce bottles at your place and thus convenient your imagination for packaging.

This method, which is a special service in the world, is being implemented by us in the Dorfam collection with sufficient knowledge and expertise, and you can contact us for advice and guidance regarding this innovative service.

The main advantages of setting up a PET production line in the factory

- The biggest advantage of the installation in your factory is that it eliminates the cost of transporting bottles, which is a very significant amount, and adds to your income.

- In today’s world, with the rapid growth of various industries, doing things is moving towards becoming more specialized in order to create more added value. Install and commissioning of production line in your factory by companies that have direct and more knowledge and experience in this challenging industry will definitely perform better in providing higher quality products at a lower cost.

- Everything is produced in the factory, where it is possible to continuously monitor the quality of the products. This leads to better control of the quality control team, thus preventing many of the problems caused by the entry of a foreign object into the bottle on the way to the factory.

- The possibility of continuous monitoring leads to new ideas in packaging. This creates flexibility in packaging and allows innovative ideas to be implemented faster and easier.

- Reduce the storage space of PET products in the factory warehouse, which in turn indirectly affects your warehousing costs.

- The commissioning of the PET bottle production line will lead to a broad partnership between PET manufacturers as backers and final product manufacturers. On the other hand, on-site production of the customer reduces the emission of greenhouse gases due to the elimination of one of the stages of transportation. It is enough to know that each ordinary passenger vehicle produces about 4.6 tons of carbon dioxide annually to know how much we have helped our environment by eliminating some city trips.

The key to PET success in the packaging industry

The secret of the success of polyethylene terephthalate lies in the properties of this material. Cheapness, ductility, beauty, transparency and radiance, ease of production with high circulation, easy use in product production lines fully automatic in all stages of filling, labeling and capping, usability in a variety of food, beverage products Chemical, hygienic and industrial, and acceptable and compatible chemical and physical properties in most of the mentioned industries, this product is in a privileged position in the polymer packaging industry and for this reason is the most widely used polymeric material in the packaging industry.

What machines do we need to commissioning a PET production line?

The types of machines required for domestic production of PET bottles depend on the needs of the factory in terms of packaging, the type of PET bottle and the type of product in which it is packaged, production capacity, customer quality perspective and finally the customer’s financial capacity. Dorfam Company has its own method for each of its customers based on the mentioned parameters and will select and offer the most cost-effective method in a way that fully satisfies the customer’s needs.

In all the offered methods by this company, quality is the main axis and the best machines with different capacities will be used according to the customer’s needs. Based on our years of experience in this method of bottle production (IN HOUSE PRODUCTION), we will offer very valuable offers to our customers and significantly reduce our customer costs.

Other production benefits on your product line

Final product companies focus on increasing the quantity and quality of their products and even seek expert advice from bottle suppliers on how to reduce costs and lower the cost of packaging.

Bottle transportation is always a big challenge due to its large volume and light weight, and it is possible to reduce this cost, which is often very significant, and add to the profit that the solution of producing bottles at the customer’s factory will be very useful in this regard.

Manufacturers of packaging polymer products (bottles) have high experience and expertise in this industry and always offer the best offers to their customers in terms of optimal bottle design in terms of optimal weight, beauty and customer attraction, ease of use, innovation in transportation Intra-organizational transportation, time planning and prevention of capital accumulation, scheduling and planning of production, warehousing and consumption are among the matters that they work on professionally.

The production industry of polymer packaging products is a very complex and special industry that the production of high-quality products continuously and without interruption with the lowest cost and highest efficiency depends on sufficient technical knowledge and experience of this industry and therefore the cost of the product by These companies are lower.

What industries are suitable for commissioning a PET bottle production line?

In various industries, factories and companies that need bottles to package their products, you can use the “method of commissioning a bottle production line at your factory”, which is known in the world as the IN HOUSE PRODUCTION method, and in fact, the higher the production of companies, the more necessary it is to use this method and reduce costs more effectively.

The most important use of PET bottles is based on their consumption in carbonated beverage factories. Various mineral, drinking and carbonated water production industries, dairy industries for packing all kinds of fresh milk without additives with limited consumption dates, producing all kinds of beer and finally factories producing all kinds of detergents and sanitary products are industries that can potentially use the method. Use “commissioning a bottle production line at your factory” to supply the bottles you need and create many benefits for the business.

If you are interested in reducing the costs of packaging, warehousing, transportation and production of the final product by commissioning a production line of PET bottles in your factory, you have to do is contact the experienced and special experts of Dorfam for initial consultation and review. We provide the best machines needed to produce the bottles you need and by installing and commissioning at your factory, we provide the opportunity to benefit from the services and full support of Dorfam while using the advantages of this method and reducing costs.