Dorfam company with the support of the best technology and advanced machines

Dependent on knowledge and expertise to produce the most complex and most beautiful polymer products required in the packing industry is not enough, and that requires a variety of advanced technologies and machines. At Dorfam Company, we have been able to produce the best products with the latest technologies in the world, with the help of the best modern machines in the plastic injection industry.

From the advantages of Dorfam company products, we can refer to the quality of products in terms of strength and impact resistance according to the type of product in which it is placed.Dorfam Company, with the experience of producing polymer products for many manufacturers, is familiar with the needs of various food, pharmaceutical and cosmetic industries, and we can give you the best consultation in the field of product packaging. By ordering your desired product to Dorfam company, Experience beauty and strength in packaging at the same time.

The role of advanced technology and machinery in the production of polymer products

Today, the use of polymer products in the packaging industry has found many applications. Only one example of these products, PET bottles of carbonated drinks with a circulation of millions, is being produced every day in the world. But the production of polymer products is impossible without having advanced machines and devices and knowledge of the new technology of the plastic injection industry. In the continuation of this article, we will get acquainted with the role of technology and advanced machines and molding methods in the production of polymer products from Dorfam Company.

INJECTION BLOW MOULDING SYSTEM

The injection blow molding method starts by heating the relevant polymer in the injection unit and the semi-molten material enters the molding unit cylindrically from the injection nozzle. After closing cylindrical mold, air blows inside the cylinder and the molten material stick to the inner wall of the mold and take the shape of the mold. Simultaneously, the cooling operation of the mold is performed by the water chiller to fix the shape of the final product. Finally, the excess material in the upper and lower parts is cut by the cutter unit and the complete and final product is produced.

INJECTION STRETCH BLOW MOULDING SYSTEM

Injection stretch blow molding technology (ISBM) also has two methods; 1-Step Injection Stretch Blow Molding 2-Steps And Injection Stretch Blow Molding

1-Step Injection Stretch Blow Molding, reduces production costs by up to 25%; Because both stages of preform production and final product production are done in one machine. The difference between this method and the extrusion blow molding method is that in this method, in addition to blowing wind into the preform, the end part of preform pulled by one arm. In 2-Step Injection Stretch Blow Molding method, first raw materials are made in the form of preforms. After cooling, to prepare for the next step, these products are heated in another machine and placed inside the mold; Then two simultaneous operations are performed, blowing air and Stretching the preform to produce the final product. The ability to create bulky parts and the possibility of selling preforms produced to other factories is one of the advantages of the 2-Steps Injection Stretch Blow Molding method. The production of the product in both methods of Injection Stretch Blow Molding, makes the contact surface between PET molecules more and the empty space between them is reduced and the final product is stronger.

INJECTION MOULDING SYSTEM

Injection molding or plastic injection method is the simplest and most widely used method of producing polymer products. This method is done using plastic injection machines. In this method, the raw material, which is in the form of granules, depending on the need, is dehumidified through large tanks that are related to the drying system and enters the extruder unit or enters the extruder unit directly. After this stage, depending on the molding, the production process of product is complete.

The injection molding method is used to produce bottle caps, preforms and a wide range of plastic parts. The raw materials used in this system may be polycarbonate, polystyrene, polyethylene, polyethylene terephthalate, polypropylene or polyvinyl chloride.

What machines do we need to produce PET products?

The advanced technology and machinery in the PET production industry have a major role. Numerous technologies for the production of PET products are performed with the help of advanced machines in this industry. Production machines in each of the production technologies of PET products are different from the machines of other technologies; Also, in each of these technologies, we can buy machines with more modern, faster and safer mechanisms at a higher cost. We review some of the machines of Dorfam company for the production of PET products:

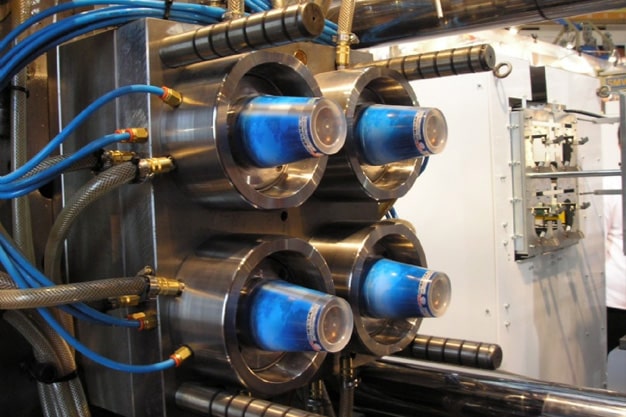

PET preform production line

The preform production industry is one of the most sensitive and so- called HI-TECH and expensive industries, which is divided into different types. From conventional preforms to special preforms, products that need to be hot-filled and packaged, so-called HOT FILL, to new technologies in the production of multi-layer preforms (Multi Layers) that increase the quality and better maintenance of products such as They have malt, milk and even carbonated beverages. Basically, the role of technology and the selection of machines and molds have a decisive role in the quality of preform production and it is very important to pay attention to preform production machines. At Dorfam Company, we have selected the best production lines to produce quality preforms so that we can satisfy our customers based on their needs.

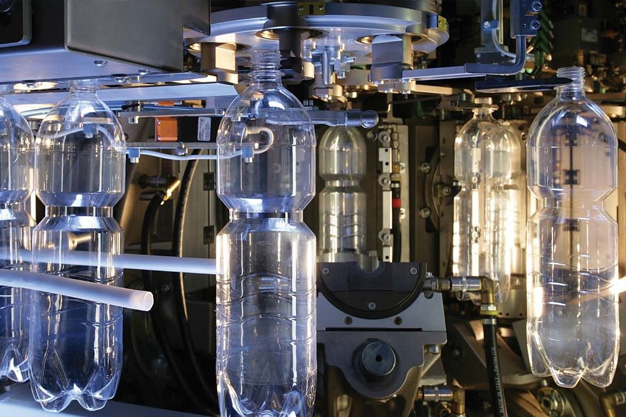

PET preform blow molding production line

Preform blow molding machines, they are used to convert preforms into bottles and these machines include a very wide range in terms of quality, capacity and type of products they produce. From manual blow molding machines whose production process involves human intervention and have very low capacities, to semi-automatic machines, and low-capacity machines, to machines with very advanced technologies that produce the highest quality bottles with They produce the lowest possible weight, with acceptable endurance, and their circulation is sometimes up to 50,000 bottles per hour. In PET blow molding lines, in addition to the blow molding machine, the required compressed air system is also of special importance and depending on the various industries, especially the food and dairy industries, the purity of the compressed air is very important. At Dorfam, we use the best technologies to produce bottles and pay special attention to quality.